The pollution of oceans and landscapes by plastic waste is increasing dramatically worldwide. Avoiding conventional plastic is therefore becoming increasingly urgent. In the BIO-PLASTICS EUROPE project, scientists and companies from all over the world have been working together since October 2019 to find alternative solutions. “Through intensive research and development, we were able to develop many sustainable strategies and solutions for the production of bio-based and biodegradable plastics as the basis for sustainable products – from reusable cutlery and toys to packaging and agricultural products,” says Dr Jelena Barbir, project manager at HAW Hamburg.

From October 2019 to January 2024, the Hamburg University of Applied Sciences (HAW) coordinated the BIO-PLASTICS EUROPE research project with 22 partners from science and industry from 13 countries. “Our aim was to develop new bio-based and biodegradable materials to support the EU Plastics Strategy and the Circular Economy Action Plan as part of the EU Green Deal,” says Barbir. In addition, strategies and business models were developed that enable efficient reuse strategies and recycling solutions while ensuring the safety of the recycled materials when used for toys or food packaging.

Partner companies tested the new materials in order to manufacture usable end consumer products from them. Among other things, various compounds were developed, composite materials with a plastic content made from sustainable raw materials. These were used to produce rigid toy material, but also reusable cutlery, packaging for cosmetics and the food sector, as well as carrier layers in self-recyclable and biodegradable packaging films. In addition, mixtures were used that are suitable for agricultural mulch films, among other things, and are self-degrading in the environment. All materials were produced from commercially available raw materials such as polymers, fillers and additives, with the polymers PLA, PHBV and natural rubber coming from renewable sources.

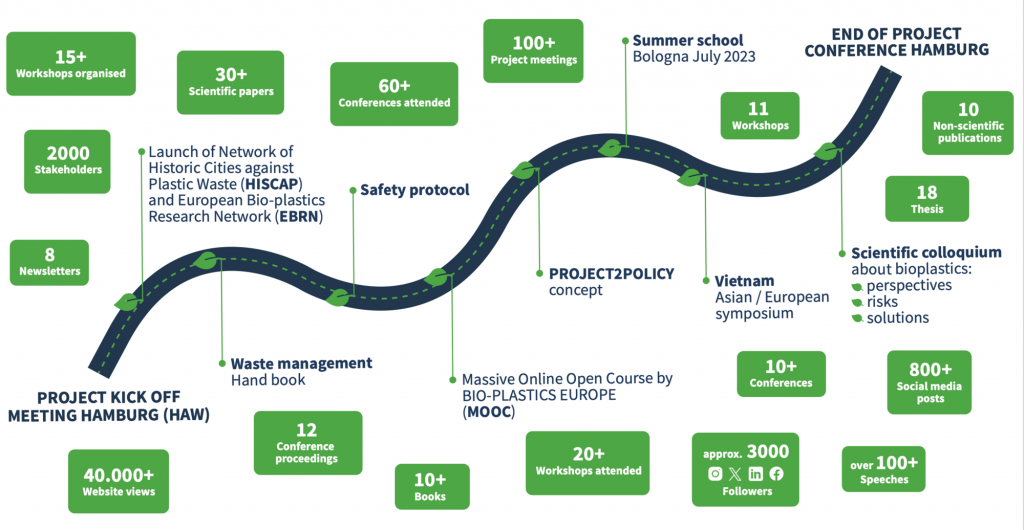

“Over the course of the project, a total of 48 research papers were published in scientific journals, five prototypes of bio-based plastics were developed and a safety protocol was created to ensure the safe use and end-of-life management of bio-based and biodegradable plastics,” says Barbir. “There is still a lot of work to be done to fully replace conventional plastic – but we are well on our way.”

Area riservata

Area riservata